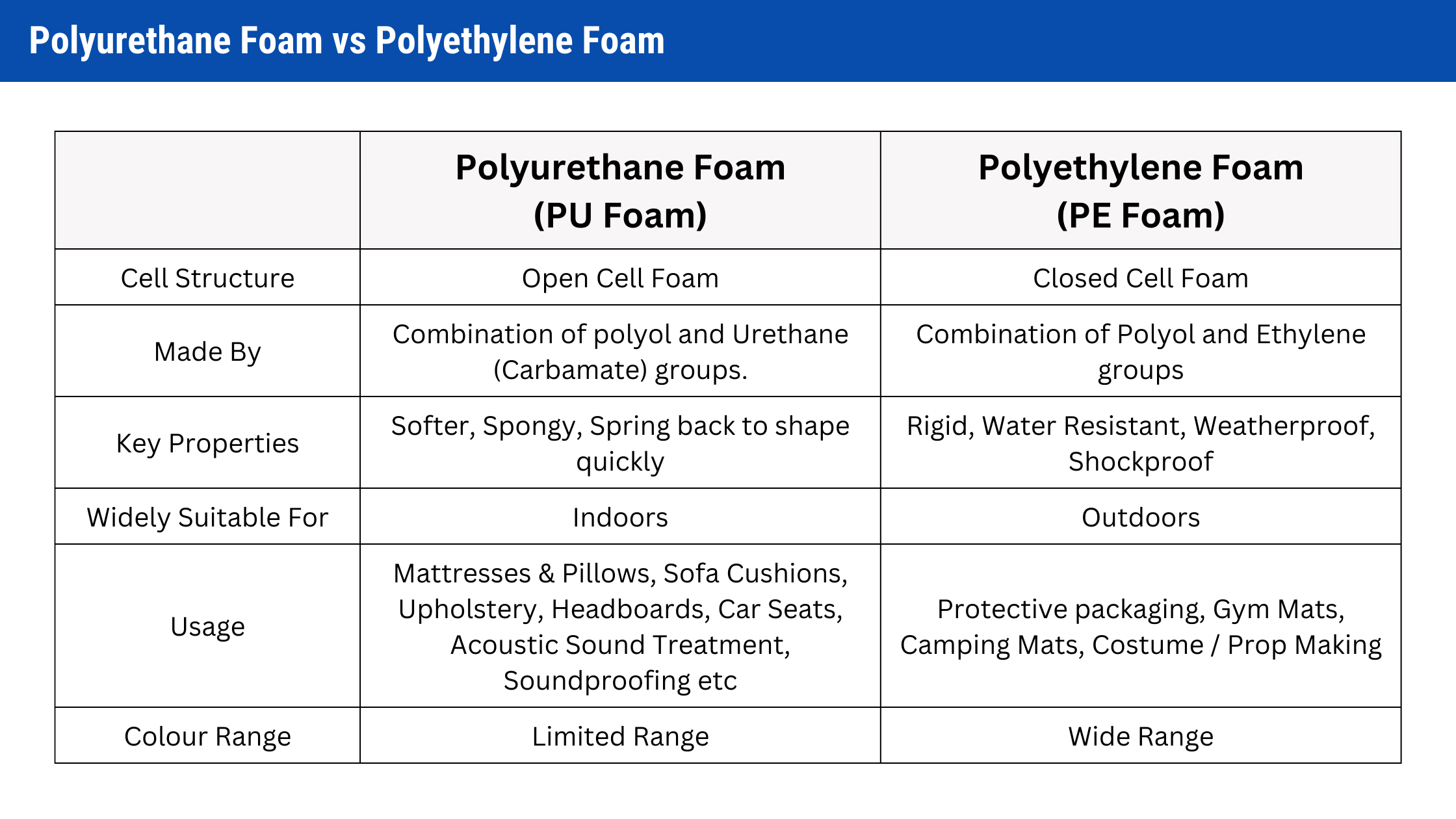

PU Foam vs PE Foam: Which is the Right Choice for Your Needs?When it comes to foam materials, two popular options frequently come into consideration: Polyurethane (PU) foam and Polyethylene (PE) foam. Both of these foams have a wide range of applications due to their unique characteristics. In this article, we will explore the differences between PU foam and PE foam to help you make an informed decision when choosing the right material for your specific needs. Polyurethane (PU) Foam

Polyurethane foam is a versatile and widely used material known for its exceptional cushioning and insulation properties. It is a polymer foam that comes in various forms, including flexible and rigid foam, each with its own set of applications. Benefits of PU Foam

Polyethylene (PE) FoamPolyethylene foam, commonly referred to as PE foam, is a lightweight and closed-cell foam material. It is renowned for its durability and excellent chemical resistance. Benefits of PE Foam

Choosing the Right Foam for Your NeedsSelecting the appropriate foam material depends on the specific requirements of your project. Here are some factors to consider:

In the PU foam vs PE foam debate, there is no one-size-fits-all answer. Both materials have their unique advantages and are suitable for various applications. It's essential to carefully evaluate your project's requirements and choose the foam that aligns with your specific needs and budget. Whether you opt for the cushioning and insulating properties of PU foam or the lightweight durability of PE foam, you can be confident that you've made an informed decision for your application. Feel free to contact us to discuss any of your requirements. |