Acoustic Foam: The Complete Guide for Beginners

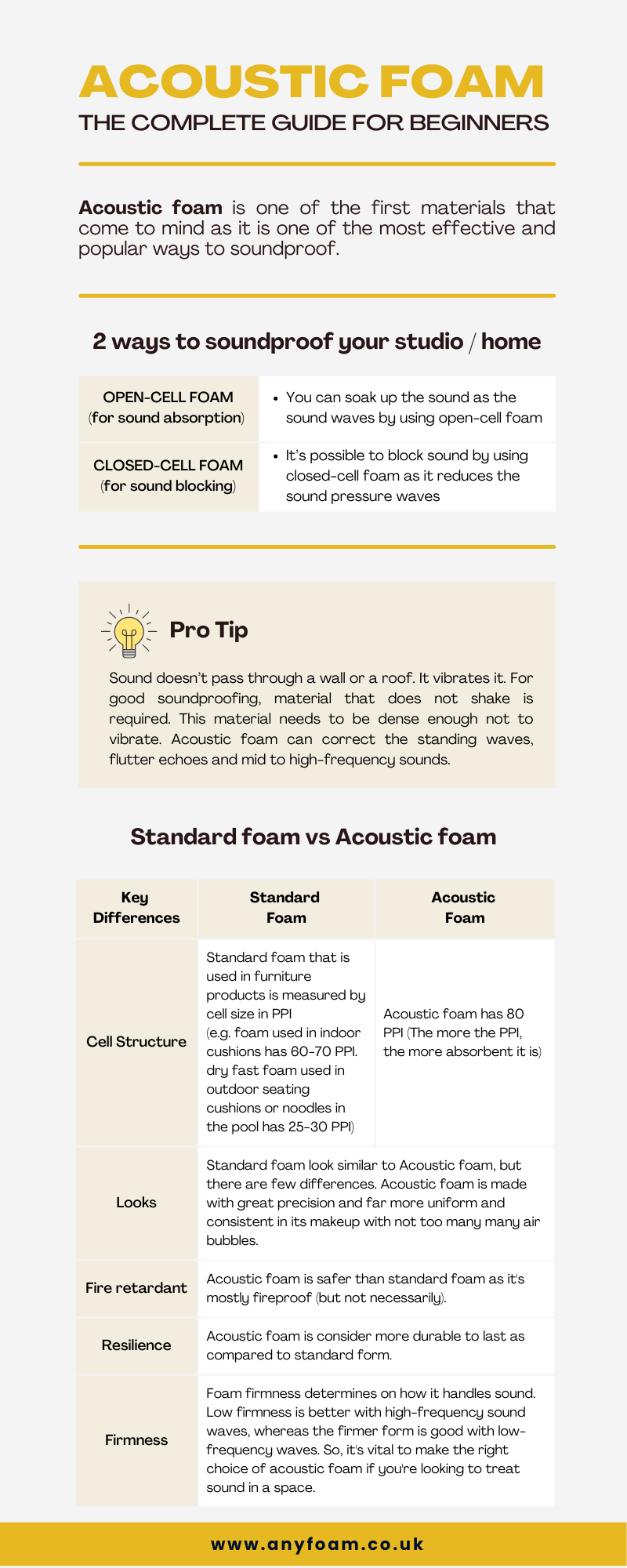

Before creating a space for sound, it’s essential to understand how to handle the sound. Acoustic foam is one of the first materials that come to mind as it is one of the most effective and popular ways to soundproof. However, there are differences in how it can be used, and it’s important to understand these so that you make the right choice. How does Acoustic Foam work?Acoustic foam can provide you with two different ways to soundproof your studio or home. A. Open-cell foam offers sound absorption You can soak up the sound as the sound waves by using open-cell foam. However, the sound will still pass through the foam, but it won’t if you use closed-cell foam. B. Closed-Cell foam provides sound blocking It’s possible to block sound by using closed-cell foam as it reduces the sound pressure waves. Whether the sound is coming from different sources or an instrument, this is effective. Acoustic foam is designed to reduce sound vibration around the room, but it won’t block it.

What is required to effectively soundproof?Sound doesn’t pass through a wall or a roof. It vibrates it. For good soundproofing, material that does not shake is required. This material needs to be dense enough not to vibrate. Acoustic foam can correct the standing waves, flutter echoes and mid to high-frequency sounds. Many of our customers ask what the difference between foam and acoustic foam is. It’s an excellent question too. As foam and acoustic foam looks so similar and feels similar, it’s something that puzzles many. Acoustic foam is made differently to open-celled foam so that you get a product that does its job well. Standard foam vs Acoustic foam: Key DifferencesIf you're looking into the arena of soundproofing your home or office studio, you may be wondering whether it's essential to use acoustic foam. You may wonder if you can apply everyday foam to catch those sound waves? Do you have to get the special acoustic foam? First off, it's vital to understand the differences between acoustic foam and other types of open-cell foam which is the everyday foam you may find in cushions and other similar objects. Of course, acoustic and conventional foam like upholstery foam look very similar, and they even feel like it. However, acoustic foam is different in that it's engineered to perform the role of absorbing sound to give you the soundproofing you need. Learn how acoustic foam differs from open-cell foam for soundproofing or say significant differences are between standard foam and acoustic foam: The structure of the cells. Foam that is used on furniture products is measured by cell size. For example, cushions will typically have a Pores Per Inch rating of 60-70. This measurement is also known as PPI. Speciality foams such as dry fast foam that is used for outdoor seating cushions or noodles in the pool will have a PPI of around 25-30.

In contrast, the measurement of acoustic foam is typically around 80. The more the PPI, the more absorbent it is. For example, if you had a piece of acoustic foam that was 12 inches x 12 inches and 3 inches thick, with a measurement of 80 PPI, it would have more than 127 million cells compared to a 60 PPI foam. How it looks. The acoustic foam must be made precisely as it has an important job to do, and it also needs to look smart as it’s exposed on the walls of studios. Therefore it’s far more uniform and consistent in its makeup. There shouldn’t be many air bubbles as they won’t look good, and they will also affect the ability of the product to deaden sound. If there are patterns cut into the foam, this will affect the way it handles sound. The acoustic soundproofing foam that we sell at AnyFoam is charcoal grey and manufactured to British Standards. We can cut to size or provide it in tiles or you can purchase it in sheets. It can be installed using our spray adhesive. Fire retardant. Although it’s not necessarily a performance characteristic, the acoustic foam must be fireproof. With electronics, wiring or even a candle, there must be some safety kept in mind. This makes acoustic foam safer than conventional foam. Resilience. As the acoustic foam is positioned to have direct contact with people, it needs to be durable enough to last. This type of foam is made so that it doesn’t create dust and is resistant to crumbling. It’s typical for a small music studio full of people, and children in home theatres and the foam can be scratched, poked or brushed. Acoustic foam is made to withstand this type of contact.

Firmness. An important consideration is the firmness of the foam. It makes a difference in how it handles sound. For example, low firmness is better with high-frequency sound waves, whereas the firmer form is good with low-frequency waves. Adding a non-acoustic foam with a firmness that is unknown can negatively impact the sound with voids. The frequencies can run rampant. You can find out all the specs of our soundproofing foam on our acoustic foam datasheet. Although all foam may have looked to be very similar before you read this piece, acoustic foam and conventional foam are very different. They are very different 'animals' and therefore treat sound in a very different way. It's vital to make the right choice of acoustic foam if you're looking to treat sound in a space. If you need any help with your acoustic foam purchase, get in touch. Our team love helping customers, and we can’t wait to hear from you. |